Contact Us For Your Roof System Replacement

Roof System Replacements

GENERAL ROOFING COMPANY HAS INSTALLED COMPLETE ROOF SYSTEMS SINCE 1924

General Roofing Company has installed complete roof systems for homeowners and businesses for almost 100 years through out the greater San Francisco Bay Area.

Only the highest quality roofing products are applied. General Roofing Company’s technicians continually engage in training and certification programs for several different roofing methods.

Sooner or later your residence or building will need a new roof.

Time, combined with weather, breaks down the existing roof surface. General Roofing Company offers a variety of guaranteed long-term solutions including:

Fiberglass Composition Shingles

Architectural, also known as laminated or dimensional shingles are among the highest quality roofing products made. Traditionally they are composed of a heavy fiberglass mat base and ceramic coated mineral granules tightly embedded in carefully refined, water-resistant asphalt.

Luxury/Designer Shingles

Laminated roof shingles designed to provide an enhanced aesthetic improving a building’s curb appeal. The shingle shape and size are modified in a way that simulates the appearance of other, more expensive types, including slate, shake & tile.

Solar Reflective Shingles

This wood shake-inspired, solar-reflective asphalt shingle reflects solar energy and radiant heat far better than traditional roofing shingles, keeping your home cooler in hot months and your roof looking great all year long. These shingles are rated by the Cool Roofing Rating Council (CRRC) and can be used to comply with the 2016 California Title 24 Part 6 Cool Roof Requirements.

Synthetic Slate or Shakes

Synthetic Composite Slate or Shakes are modeled from actual slate or hand-split shakes and made from virgin resins fortified with state -of-the art UV stabilizers for a natural, non-repeating beauty.

Concrete or Clay Tiles

Tile Roof Systems allow you to achieve either an authentic, old world feel or an up-to-date modern look using current technology. The different styles are designed to replicate the customer’s preferred characteristics such as slate, clay and wood.

Cedar Shingles and Shakes

A shake is a basic wooden shingle made from split logs. Higher-grade shakes are typically used for roofing purposes. Properly installed shakes provide long-lasting weather protection. A wood roof system tends to require more maintenance than most other roof surface.

Modified Bitumen Built-up Roof Systems

Modified Bitumen is asphalt that has had modifiers added to it to give it plastic or rubber-like properties. The most common types of modifiers being used are APP (Atactic Polypropylene) and SBS (Styrene Butadiene Styrene). This system is usually mopped, heat applied or self-adhered).

Metal Shingles

A metal roof can make an ordinary home extraordinary. Metal roofing gives your home the authentic look, design and natural detail of real wood shake, quarried slate, or traditional clay tile roofing, with performance that’s stronger than steel. The advanced technology of metal shingles reduces your home’s heat in hot weather and complies with the 2016 California Title 24 Part 6 Cool Roof Requirements.

PVC Single-Ply Roof Systems

PVC (Polyvinyl Chloride) roof systems are ENERGY STAR qualified and CRRC (Cool Roof Rated Council) certified. They offer the potential for decreased cooling costs and excellent resistance to rooftop chemical attacks including acids, oils and greases.

TPO Single-Ply Roof Systems

TPO (Thermoplastic polylefin) membranes are ENERGY STAR qualified and CRRC (Cool Roof Rated Council) certified. TPO roof systems have been directly attributed to reducing a building’s energy consumption by greatly diminishing the cost of air conditioning.

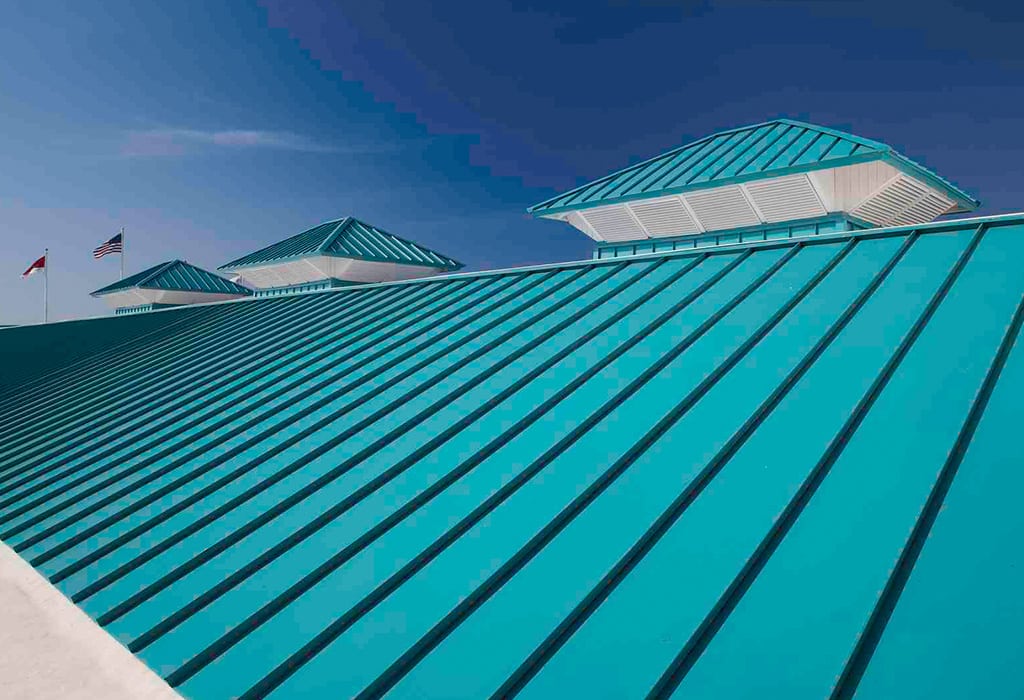

Standing Seam Metal Roof Systems

One of the oldest and most practical roofing solutions, Standing Seam Metal Roofing enhances the roofline of virtually any architectural style.

Roof Coatings

PROTECTION AND EXTENSION OF ROOF LIFE

Roof coatings are designed for protecting and extending the useful service life of roof assemblies for new construction and more commonly, existing roof coverings such as Built-up roofing (BUR), metal, modified bitumen, single ply membranes and sprayed in place polyurethane foam. Reflective coatings can also reduce heat energy costs and improve the aesthetics of the roof.

The most common types of roof coatings are acrylic, asphalt polyurethane and silicone. Coatings can also be made with other resins or combinations of resins. These include, but are not limited to, butyl resins, fluoropolymer, Polymethyl methacrylate, polyester, silyl terminated polyether, polyuria, and styrene-acrylics.

The typical life expectancy of a properly applied coating can extend the roof life up to ten years or more depending on the product manufacturer’s warranty. Performance varies depending on type, conditions and coating film thickness. As the coating wears away, additional coating may be applied. Most coatings are renewable and sustainable.